AT WORK

- Very high cutting speed, fully variable from 500 up to 5000 rpm.

- Slow mixing speed, variable from 50 to 500 rpm, forward and reverse.

- German BE-Maschinenmesser knives, made of special high-resistance KUT steel. Minimum space between all knives and the bowl thanks to its large central diameter.

- Four on-screen buttons for direct selection of knife and bowl speeds, freely configurable.

- Motorized stainless steel knife lid for effortless lifting and lowering.

- Transparent noise protection cover with CE safety clearance reduces knife speed while open; returns to previous speed when closed.

CUTTING MECHANICS

- Removable 6-knife head and compensating rings for use with 3 knives.

- Simplified knife shaft, highly reliable, with advanced quality bearings and seals designed for high revs, with a 2-year guarantee.

- New vibration reduction technology at high revs, developed in collaboration with UPV Polytechnic University.

Excellent professional results with meat, vegetables, vegan/vegetarian food, fish, and special dough.

S/S FRAME

- Completely stainless: the entire frame, both external and internal components, are made of AISI304 stainless steel, including all possible hardware and components.

- Very robust construction, with a heavy machine weighing approximately 900 kg.

- Solid, 90 kg cast stainless steel bowl, featuring an outer rim to prevent liquids or dough from spilling.

- Low bowl height for more comfortable use.

- Bowl equipped with a drain plug.

- Adjustable stainless steel machine feet, designed to be non-slip and absorb vibrations.

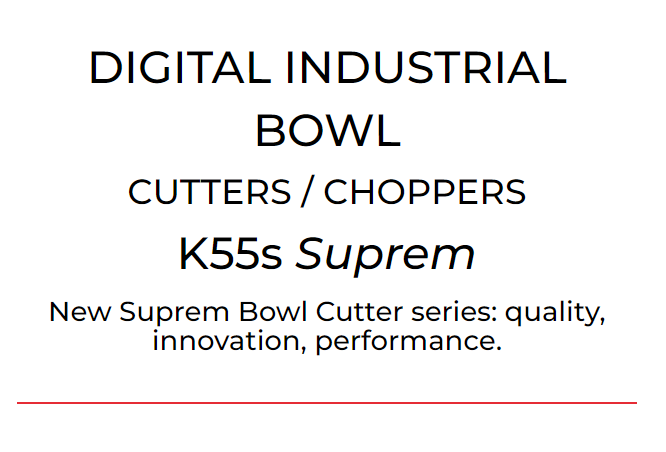

CLEANING

- Machine body surfaces with drainage slopes to prevent stagnant water and simplify cleaning.

- Polished surfaces without corners, featuring CE radius to facilitate cleaning and comply with hygiene standards.

- Large, removable bowl scraper.

- Double-sealed waterproof access panels.

- Closed machine bottom.

- Removable friction seal between lid and bowl,

equipped with self-adjusting springs.

ELECTRICS AND ELECTRONICS

- Powerful motors designed to quickly process compact and chilled dough.

- Two options available for knife-motor powers.

- Soft start and stop of knives and bowl facilitated by two-speed drives.

- High energy efficiency class IE3, utilizing high-performance ABB motors and last-generation drives.

- Automatic knife safety stop feature.

- Thermal motor protection included.

- Fast and sensitive digital thermometer with a sensor extending into the internal cavity of the lid.

- Folding internal electric panel for easy access, equipped with a temperature-controlled cooling system.

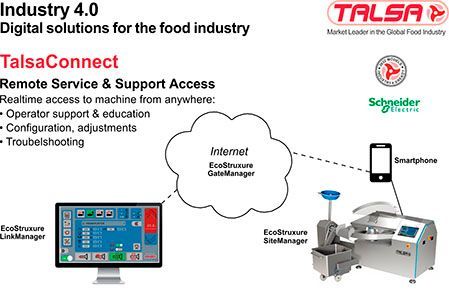

- Electronic and electric components from top brands such as Schneider Electric and ABB.

SOFTWARE AND EXTERNAL CONNECTIONS

- Control panel with a large 15” Schneider Electric digital touchscreen, displaying all information simultaneously and in large size.

- Extensive information on controls, alarms, errors, and diagnostics.

- Very advanced and practical software with numerous automatic stop options, making it intuitive and easy to use.

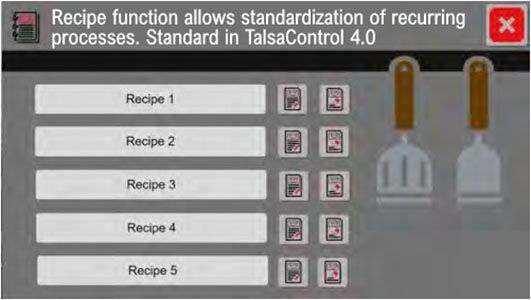

- Interactive recipes that can be stored and executed directly on the machine’s screen.

- New Talsa EcoCut Power Control feature to determine the machine power required to achieve desired cutting results at any time during the process.

- Industry 4.0 digital solutions for maintenance, process integration, and custom solutions.

- Remote Service and Support access

over a secure internet connection (router/ethernet or mobile phone).

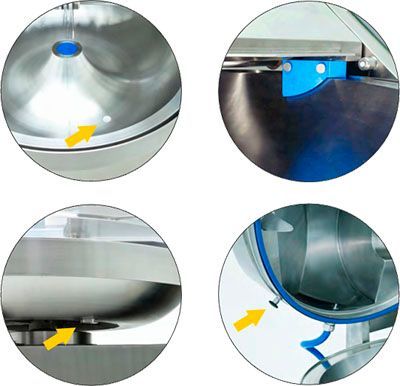

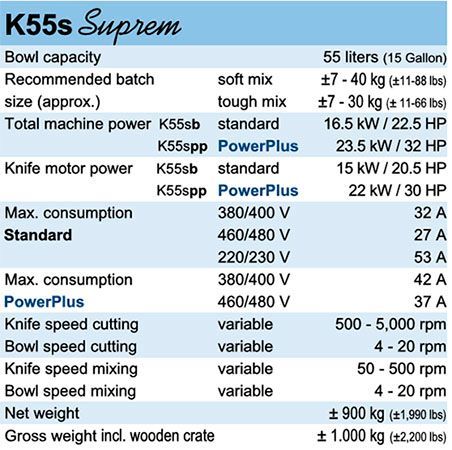

TECHNICAL SPECIFICATIONS

Important advice: always opt for a large bowl cutter capacity and power to accommodate future production growth. Available Talsa capacities include 15, 30, 55, 95, 135, and 200 liters.