Advantages at a glance

- Very high cutting speed, fully variable from 500 up to 3500 rpm.

- Smooth start of knives due to electronic drives, overload protection.

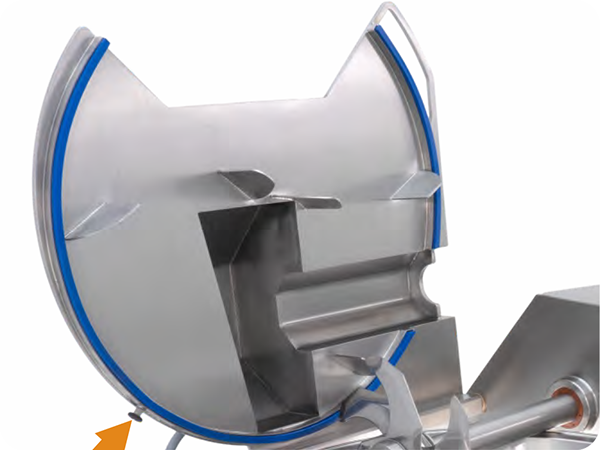

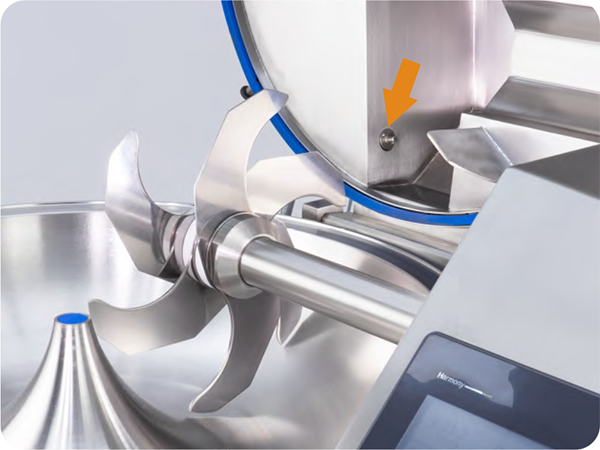

- German BE-Maschinenmesser knives, special high resistance KUT steel. Minimum space between all knives and the bowl thanks to its large central diameter.

- Simplified knife shaft, very reliable, with advanced quality bearings and seals for high revs, 2 years guaranteed.

- Strong, all stainless steel construction, solid bowl and lid.

- Electric device to prevent condensations inside the machine frame.

- Adjustable, non-slip and vibration absorbing stainless steel machine feet.

- Excellent professional results with meat, vegetables, vegan/ vegetarian food.

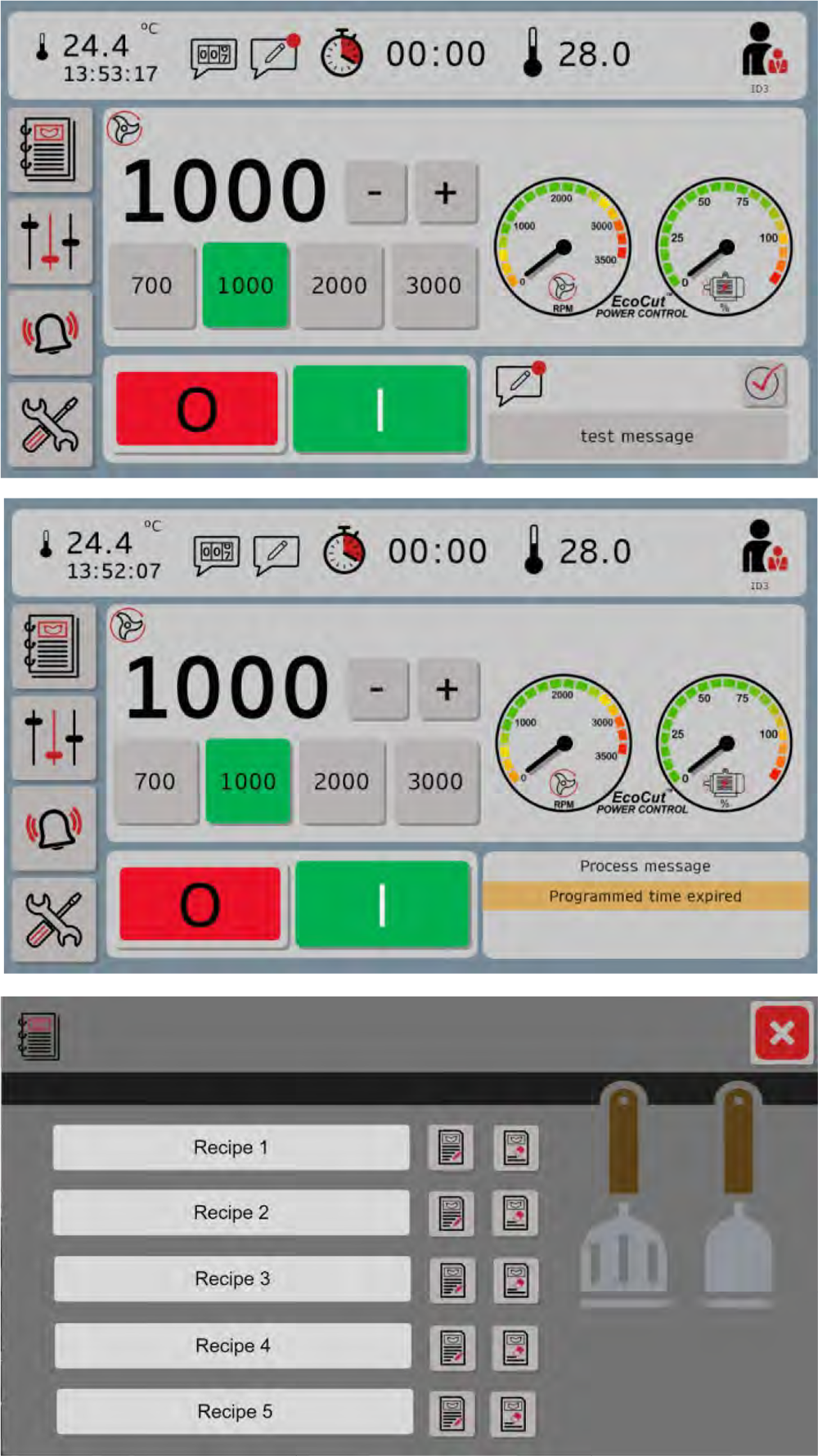

Recipe function allows standardization of recurring processes. Standard in TalsaControl 4.0

Software and external connections

- Control panel with a large 10” Schneider Electric digital touchscreen, displaying all information simultaneously: knife speed, temperature, elapsed time, and current time.

- Four speed preselection buttons for knife speed, freely configurable.

- Very advanced and practical software with automatic stop options, triggered by temperature limit and/or elapsed time. Intuitive and easy to use.

- Interactive recipes that can be stored and executed directly on the machine’s screen.

- Talsa EcoCut Power Control to determine the machine power required to achieve the desired cutting results at any time during the process.

- Industry 4.0 digital solutions for maintenance, process integration, and custom solutions.

- Remote Service and Support access via secure internet connection (router/ethernet or mobile phone).

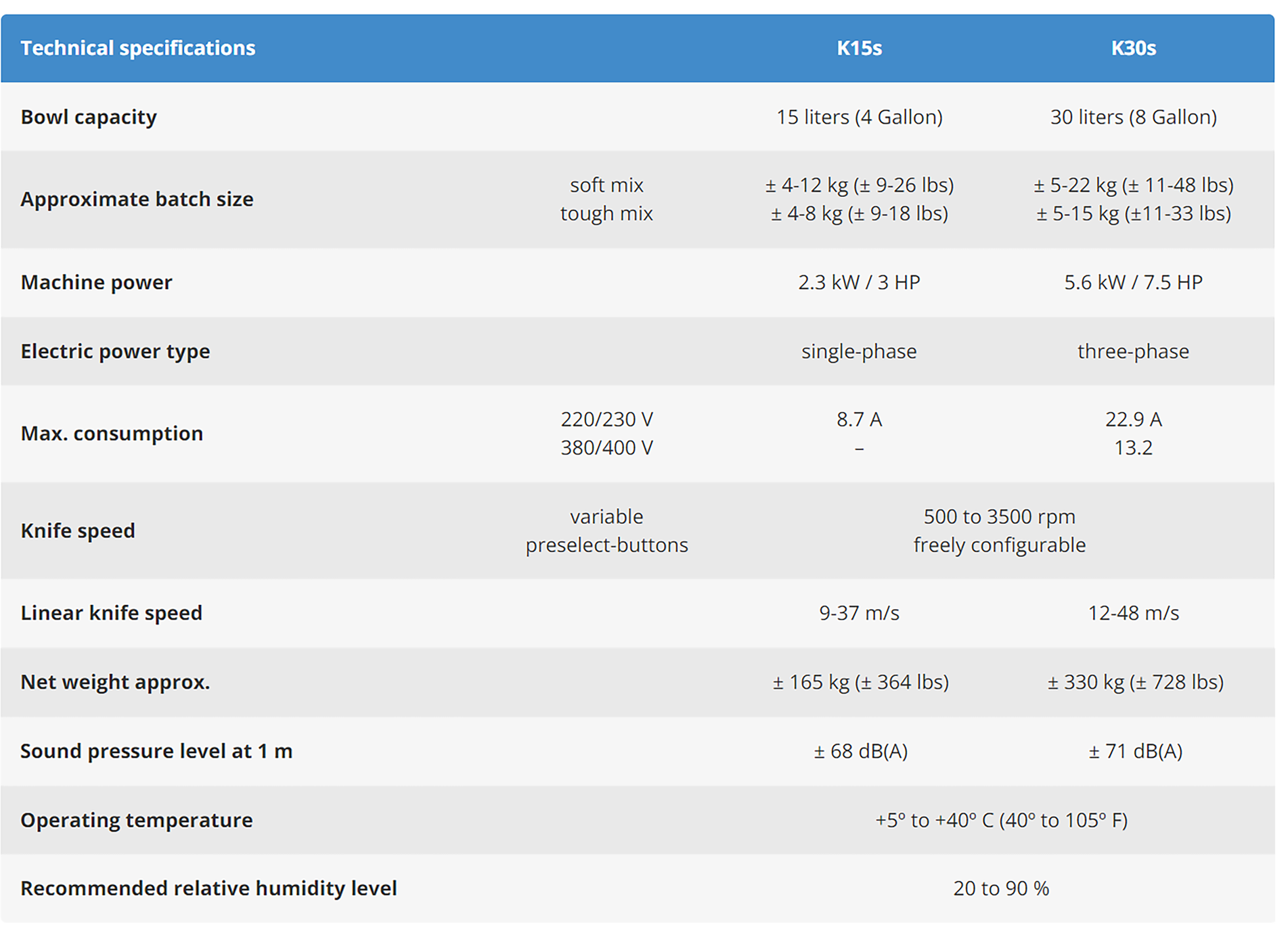

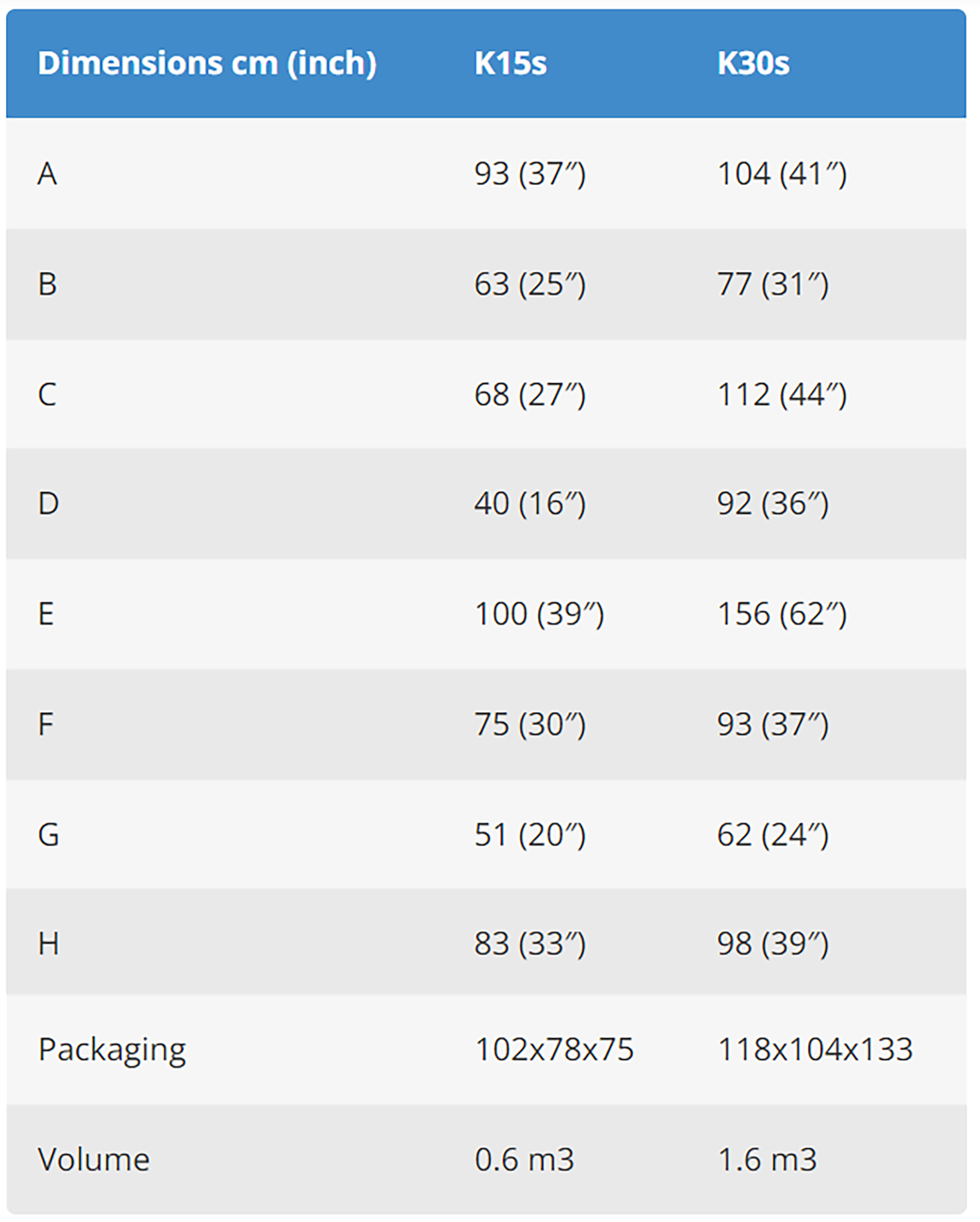

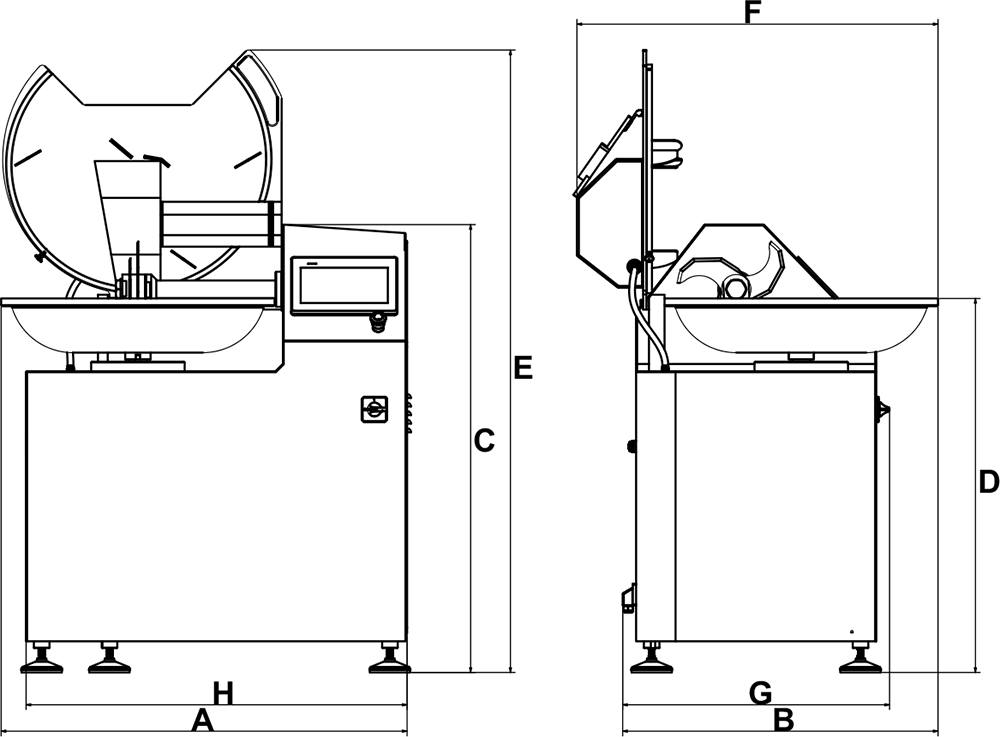

Technical Data

Important advice: Always choose a large bowl cutter capacity and power to accommodate future production growth. Available Talsa capacities include 15, 30, 55, 95, 135, and 200 liters.