Outstanding features

The Talsa K200ns bowl cutters/choppers are specifically designed for the production of sausage hash of all kinds, catering to large slaughterhouses and industrial meat processors.

Moreover, they are versatile and suitable for a wide range of applications including poultry, fish, pastry, alternative protein or vegetarian products, processed cheese, and various other commodities in the food processing industry.

The K200ns model excels in cutting, mixing, and emulsifying all types of food products, accommodating thick to very fine textures.

Additionally, these machines are user-friendly with an automated control system, making operation simple. They are also designed for easy cleaning and maintenance, ensuring efficiency and convenience in food processing operations.

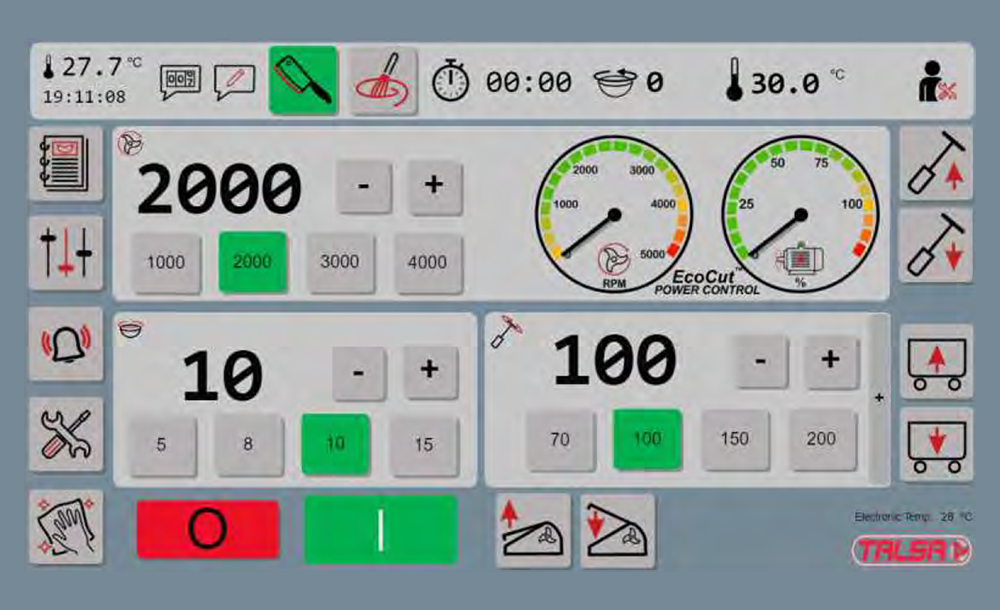

TalsaControl 4.0

- Digital display indicating knife and bowl speed, temperature, turns, elapsed time, and current time.

- Automatic stop functionality based on elapsed time, temperature, and turns of the bowl.

- Display of maintenance and service intervals.

- Interactive recipes for enhanced operational efficiency and convenience.

Innovative Design

R&D project on vibration and sound reduction in cooperation with the Polytechnic University of Valencia, Mechanical Engineering Research Centre:

- Fully 3D computer modeling designed.

- Vibration reduction implemented on the knife shaft.

- Reduction of noise and vibration in the chassis.

- Implementation of silent drive transmission for reduced noise levels.

Advantages at a glance

- Detachable 6-knife head and compensation rings for use with 3 knives.

- High-quality knives from BE-Maschinenmesser (Germany), adjustable to minimum distance to bowl.

- Optimized cavity design utilizes the bottom of the stainless steel lid for cutting as well.

- Temperature sensor (ºF/ºC) located in the cutting cavity for precise measurement of mix during operation.

- Knife shaft designed using dynamic 3D modeling to achieve further reduction of vibrations.

- Control panel with large 15″ digital touch screen.

- Variable high cutting speed from 500 to 4.000 rpm.

- Slow mixing speed variable from 50 to 500 rpm, forward & reverse.

- Variable bowl speed from 4 to 20 rpm.

- 4 programmable speed buttons for each function.

- Variable unloader disc speed from 50 to 150 rpm.

- Bowl capacity for the K200 model: up to approximately 160 kg of soft meat or approximately 100 kg of tough/frozen meat.

- Equipped with a hydraulic loader for standard 200-liter trolleys and a motorized hydraulic unloading arm to empty into the trolley.

- Features a motorized stainless steel knife lid for effortless lifting and lowering.

- Includes a noise protection plastic cover with CE safety clearance, ensuring that the knife speed reduces when opening and returns to the previous speed when closing.

- 100% stainless steel AISI304 construction.

- Very solid construction with a strong machine frame.

- Solid bowl made of robust stainless steel cast, featuring a liquid drain plug.

- Adjustable NGI Denmark feet, designed to be non-slip and absorb vibrations.

- IP65 watertight electric cabinet.

- Maintenance-free bearings with a 2-year warranty.

- Polished surfaces, without corners, featuring a CE radius to facilitate cleaning and comply with the highest hygienic requirements.

- Hygienic labyrinth in the knife head to prevent meat dough from entering the shaft/bearings.

- Electric heating device to prevent condensation inside the machine.

- Bottom of the machine closed with labyrinthine breathing slots.

High power to cut compact and even solid frozen meat.

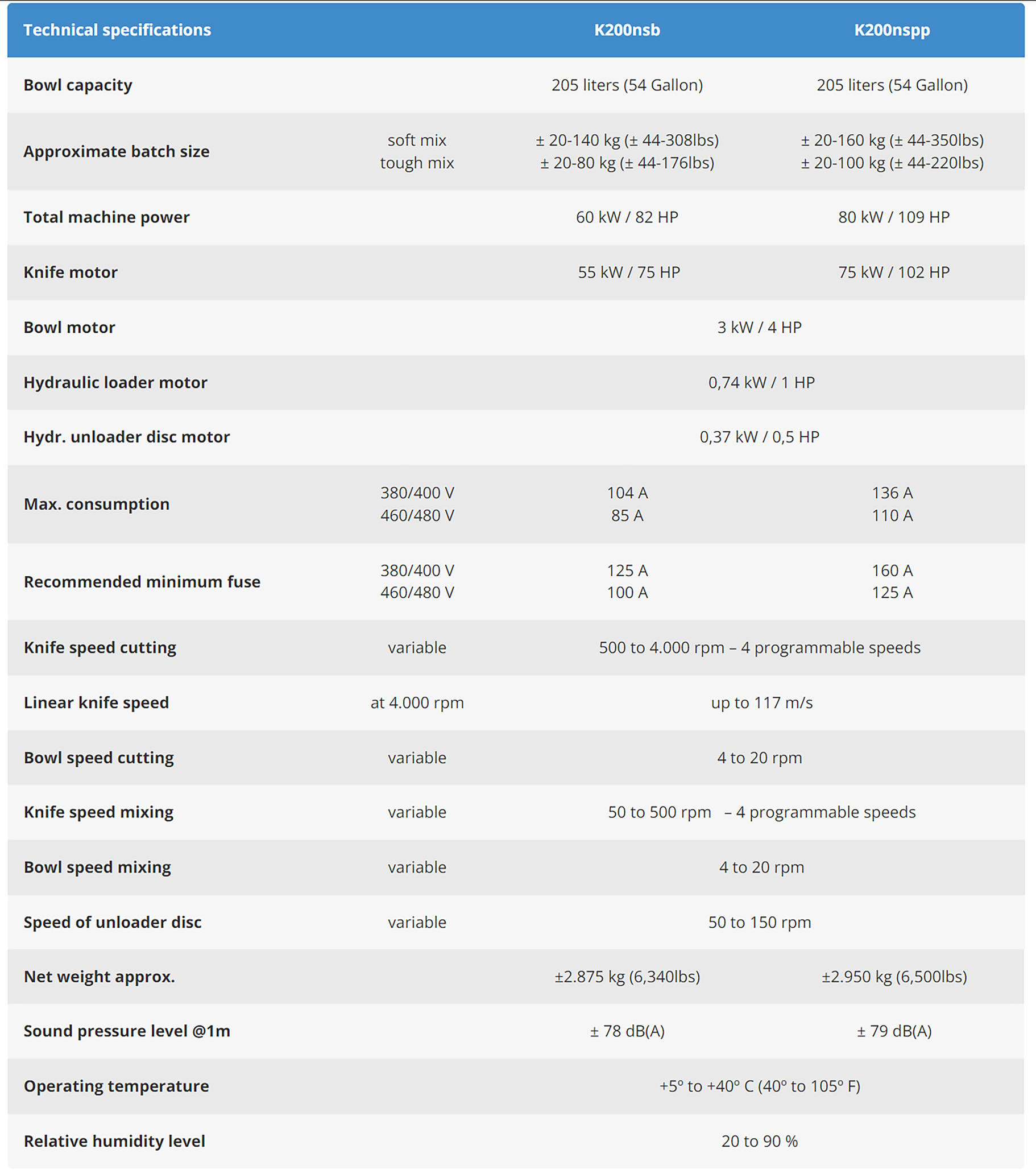

- K200nsb: 82HP/60kW,

- K200nspp (PowerPlus): 109HP/80kW.

- High energy efficiency class IE3 globally, with high-performance ABB motors and VDF electronic frequency converters.

- Smooth starts and stops of knives and bowl due to next-generation electronic frequency converters.

- Automatic electronic knife safety brake included.

- Thermal protection provided on all motors.

- Standard voltage 400/380 V, with other voltages available.

Knife Head with 6 standard knives BE-Maschinenmesser (Germany)

Software and external connections

- Control panel equipped with a large 15” Schneider Electric digital touch screen, displaying all information simultaneously and in large size.

- Extensive information provided on controls, alarms, errors, and diagnostics.

- Very advanced and practical software with numerous automatic stop options, ensuring an intuitive and easy-to-use interface.

- Interactive recipes available, which can be stored and executed directly on the machine’s screen.

- New Talsa EcoCut Power Control feature allows determination of the machine power required to achieve the desired cutting results at any time during the process.

- Industry 4.0 digital solutions offered for maintenance, process integration, and custom solutions.

- Remote Service and Support access available over a secure internet connection (router/ethernet or mobile phone).

Technical specifications

Important advice: Always opt for a large bowl cutter capacity and power to accommodate future growth in production. Available Talsa capacities include 15, 30, 55, 95, 135, and 200

liters.